Believe it or not, time tracking isn’t a modern invention. In industries like manufacturing, engineering, and construction, it appeared thousands of years ago. In ancient Egypt, managers (if we can call them so) used clay tablets to record hours and determine how much payment or food a specific worker or slave would get. Then came sundials and later—water clocks, candle clocks, hourglasses, oil lamps, and so on, and so forth.

In the 19th century, the age of the Industrial Revolution, when factories began popping up everywhere, keeping track of worker hours became a bit more complicated.

In 1888, Willard Le Grand Bundy, a jeweler from New York, invented a device that recorded hours worked by the employees. Imagine a big ol’ machine where workers would punch holes in a card to record their hours. It was simple, effective, and became a game-changer for employers trying to manage large workforces.

In this post, however, we are going to talk about the modern era.

As we rolled into the late 20th century, technology began to take over (as it tends to do). The introduction of computers brought about a whole new world for time tracking. No more punch cards! Instead, companies started using software to track hours worked. Employees could log their time on a computer, making it easier for managers to keep tabs on productivity.

Today, high-quality time trackers produce even more immense benefits for manufacturing businesses. And this article discusses these benefits in detail, focusing on the specific needs of every production team and the essential qualities to look for in a manufacturing time tracking solution.

The Present and Future of Manufacturing Time Tracking

At its beginning, manufacturing time tracking software was all about calculating employee work. People were paid by the hour, and the primary goal of the tool was to accurately record the start and the end of the workday. So it would be fair to say that it all started with clock-in-clock-out solutions.

These tools track hours worked in real-time, as employees log into the software using unique credentials (username and password) or other authentication methods (like biometric scans or QR codes), helping employees to be more mindful of their hours and giving managers more time to focus on strategic tasks…

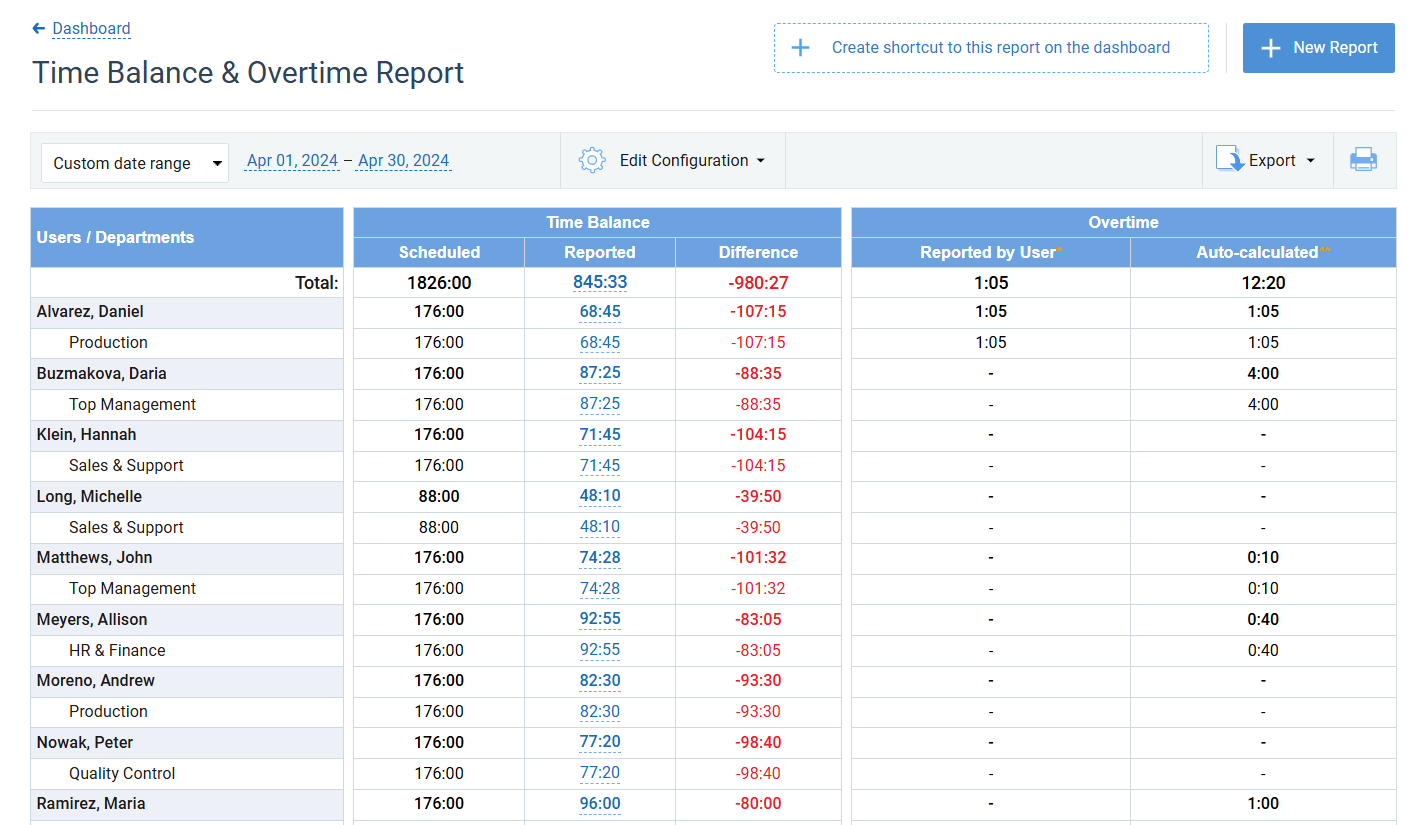

Actually, clock-in-clock-out software does much more than that: it tracks how many hours each employee works in a given period, helping ensure accurate payroll, and automatically calculates overtime hours, making it easier for managers to approve and compensate employees correctly.

Many systems also track breaks and lunches, which is crucial for compliance with labor laws and ensuring employees are taking their necessary downtime. Alongside classic clock-in and attendance systems, some manufacturers use tools like actiTIME to go a step further and record time against jobs, tasks, or production activities, while still handling payroll hours, overtime, and approvals in one system.

Now let’s take a look at some real-life examples. TimeClockPLus offers a digital solution for staff to record their working hours through various options, including a physical time clock, a web interface, or a mobile application.

This system automatically gathers time and attendance information, which managers can utilize to oversee schedules, monitor time off, and handle payroll with reduced manual effort. Certain versions of the system enable employees to monitor the time allocated to specific jobs, tasks, or projects.

Sounds good, doesn’t it? But still not enough. Imagine a manufacturing company with multiple job sites. Employees might be working on different projects at various locations throughout the week and sometimes throughout the day.

Then, it becomes crucial for a manager to know where exactly they are at a given moment, and that’s where geofencing comes into play. A geofence is a virtual boundary created around a specific location using GPS or RFID technology. When employees enter or exit this boundary, their device can clock them in automatically, ensuring that they’re only paid for hours worked at specific locations and simplifying client billing.

The geofencing feature is usually offered by bigger manufacturing time-tracking platforms, such as Connecteam, Homebase, or Hubstaff.

So, can we say that clock-in tools have all the needs of the manufacturing industry covered? It actually depends on how you perceive time. The years when companies would tally up how many hours employees clocked in and out, assuming that more hours meant more profit, sank into oblivion.

As the market becomes more competitive, manufacturers are realizing that efficiency—essentially the quality of the output per hour worked—is a much better gauge of success.

Measuring Performance and Efficiency

It’s not just about how much you produce; it’s about how well you produce it!

Unlike productivity, that is mainly concerned with the quantity of outputs, efficiency indicates that your employees do their job well and not merely seem that way.

By honing in on efficiency you streamline processes, reduce waste, and increase production rates without necessarily extending work hours. And optimization, in turn, lets you uncover opportunities to improve output quality and encourage your team to innovate and refine their methods, resulting in superior products that meet customer expectations.

To analyze performance efficiency, you need to identify the standard number of hours required to complete a piece of work / produce a certain quantity of goods and then divide it by the actual amount of time used to complete the task. Then, you need to multiply the result by 100 – the closer your final number is to 100, the higher efficiency your employees show.

Monitoring Manufacturing Efficiency: actiTIME Tips

When efficiency becomes your key metric, instead of just knowing when someone was at their desk or on-site, it would be more useful to understand:

- What specific tasks were completed during that time?

- Did the work contribute to the project’s outcome?

- How easy was it to complete those tasks compared to previous projects?

- and more.

That’s where tools that focus on task management and project outcomes and encourage your team to log their tasks and reflect on their work processes, will give you more insights than all the clock-in and geofencing data in the world.

Track Work Hours Wisely

Of course, when we speak about shifting focus to efficiency, that doesn’t mean throwing time tracking out the window. It means finding a middle ground where employees can log their hours in a way that suits them while still meeting business goals.

This means, first, combining the automatic time tracking functionality with manual input features, and second, linking timesheet entries to specific activities, as staying at the workstation for eight hours doesn’t mean actually being productive.

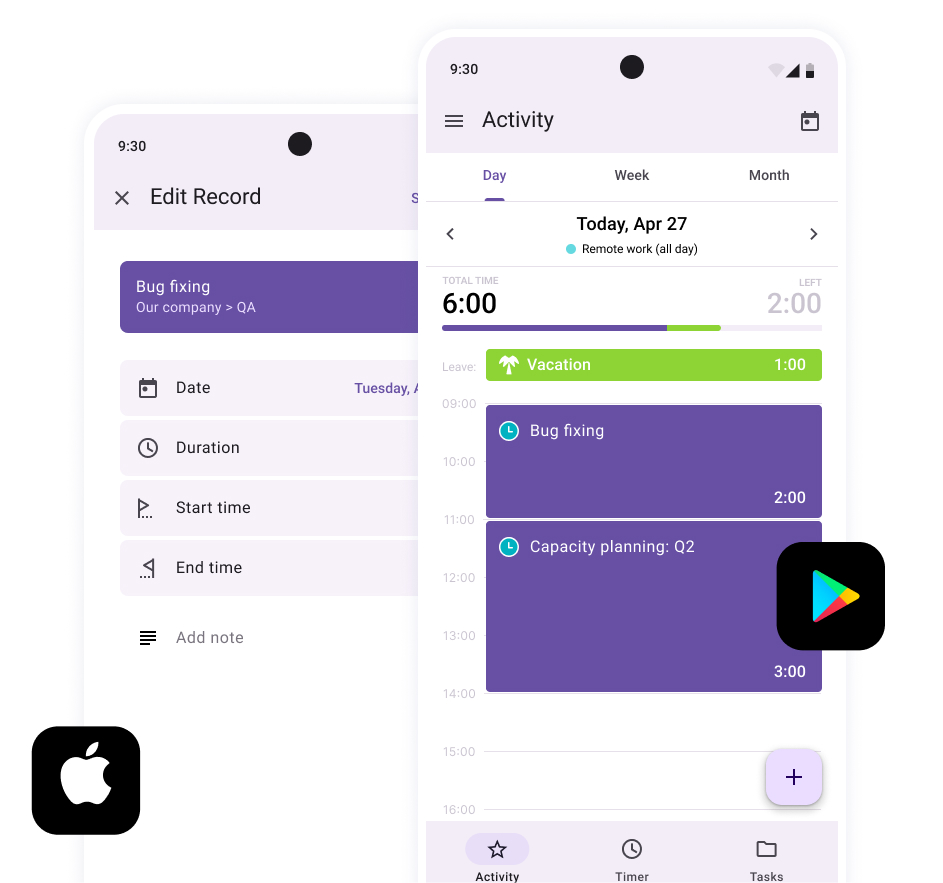

Tools like actiTIME , which offer both flexible time tracking and task management features, will allow your workers to log their work hours from desktop and mobile, assign time tracking to a selected project or task, and comment on each entry to provide substantiation.

Pro tip: We all know that while providing unprecedented precision, GPS and clock-in tools can lead to anxiety. Your workers might rush through tasks just to meet a time requirement or feel pressured to stay longer than necessary to “look good” on paper. On the other hand, when you rely on manual entry only, small tasks can simply get lost.

A good mobile app and a browser extension will help you find the sweet spot.

These allows automated tracking or using one-click timers from just anywhere and, thus, minimize the risk of workflow interruptions on the production floor.

Besides that actiTIME mobile supports time tracking in offline mode. When applying it, you merely need to:

- Select a task from the list

- Launch the timer before engaging in work

- And stop it once the task is completed

Even if the internet connection is lost, the submitted data is saved in the app and becomes available for a manager’s review in the corporate actiTIME account whenever a user is back online.

Utilize Historical Data to Make Accurate Work Estimates

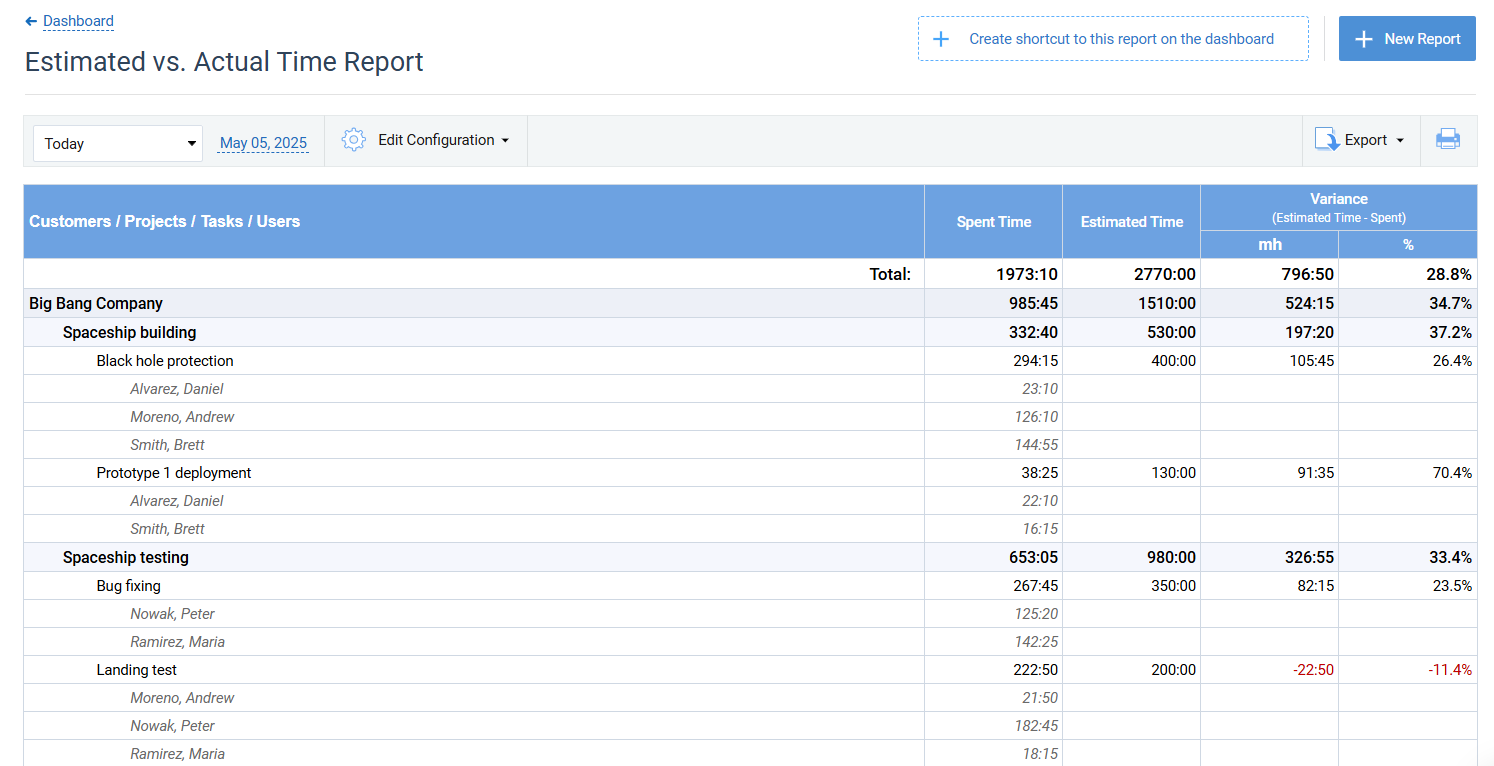

Another powerful tool at your disposal for achieving and measuring efficiency is work estimation. By accurately estimating the time and costs associated with your projects, you can create a robust plan that sets your team up for success.

A particularly effective estimation method is analogous estimation. This technique involves leveraging data from past projects to inform your current plans. Here’s how you can implement it in three simple steps:

- Start by outlining a comprehensive plan for your upcoming project. Break down the project into specific tasks and milestones to identify all necessary resources.

- Next, look back at similar projects your team has completed in the past. Retrieve all relevant data regarding their financial performance and analyze how your team utilized their time throughout those projects.

- Using the insights gained from your analysis, create new task estimates for your current project. Consider both the financial data and time usage patterns from previous projects to inform your predictions.

Pro Tip: By combining analogous estimation with time tracking, you can make informed decisions that lead to better project budgeting and scheduling. The ability to reference past performance allows you to avoid common pitfalls and set realistic expectations for your team.

Enhance Resource Allocation

Now, to your resources. Assigning the right tools, materials, and manpower to the right tasks at the right time is a game-changer for improving efficiency in all kinds of production. Remember Toyota, famous for its super-effective lean manufacturing principles. In the early 2000s, they faced challenges with production delays and increased competition. Certain assembly lines were experiencing bottlenecks, leading to longer lead times and higher operational costs.

To resolve these issues, Toyota implemented a comprehensive time tracking system across its assembly lines. This system recorded how long each task took, the number of units produced, and the downtime for machines.

The data collected revealed that certain stations on the assembly line were consistently slower than others. For instance, one station responsible for installing electronic components was taking significantly longer due to a lack of skilled labor and inefficient processes.

Based on the insights gained from time tracking data, Toyota took several actions:

1. Reallocation of Labor: The company identified skilled workers in other areas who could be temporarily reassigned to the slow station. This helped balance the workload and reduce delays.

2. Process Redesign: They analyzed the workflow at the bottleneck station and identified unnecessary steps that could be eliminated. By streamlining this process, they reduced the time required for assembly.

3. Training Programs: Toyota invested in training programs for employees to enhance their skills in critical areas. This not only improved efficiency but also boosted employee morale and engagement.

4. Equipment Upgrades: The data indicated that some machines were frequently breaking down or operating below capacity. Toyota decided to invest in newer, more reliable equipment for these stations, further enhancing productivity.

Tools like actiTIME also help you gather valuable insights into how time is spent across various tasks and processes and reveal:

- Where Time Is Spent: Are certain tasks taking longer than expected? Time tracking can help identify bottlenecks in production.

- Employee Productivity: You’ll get a clearer picture of how individual team members are performing and where they might need support.

- Resource Utilization: It allows you to see if certain resources (like machines or labor) are being overused or underused.

Pro tip: If time-track shows that a specific stage in your production process is consistently delayed, it might be time to re-evaluate how resources are allocated there. Maybe you need more hands on deck or perhaps an upgrade in equipment. With the right time tracking data, you can monitor workloads across your team and redistribute tasks as needed to prevent burnout and keep morale high.

The Bottom Line

As the old notion of time as merely a quantifiable resource is shifting towards a more nuanced view, the process of tracking it is also evolving from simple hour counting to a comprehensive analysis.

Businesses are increasingly focusing on metrics like project completion rates, efficiency, and overall output, which means not just quantifying hours spent on tasks but capturing the quality of those hours and assessing not how long employees work, but how effectively they engage with their tasks.

Traditional clock-in and geofencing tools simply can’t meet the diverse needs of modern time tracking, and it bocomes essential to adopt more comprehensive solutions that combine time tracking and attendance monitoring with project management and advanced analytics.

So, if you haven’t already made the switch to a digital time-tracking system, it might be time to start an actiTIME free trial giving yourself a chance to focus on quality over quantity!

![9 Best Contractor Time Tracking Apps for 2026 [Free & Paid]](https://www.actitime.com/wp-content/uploads/2020/10/how-to-find-efficient-contractor.png)